Fall Protection Solutions: The Comprehensive Guide

Beyond Basics: Evaluating and Implementing the Ideal Fall Protection Solutions for Your Facility

fall protection solutions should I implement at my facility? Which solutions will work best for our teams and contractors to consistently create a safe work environment? When selecting the best fall protection solutions for your organization we’ll be evaluating and considering these factors:

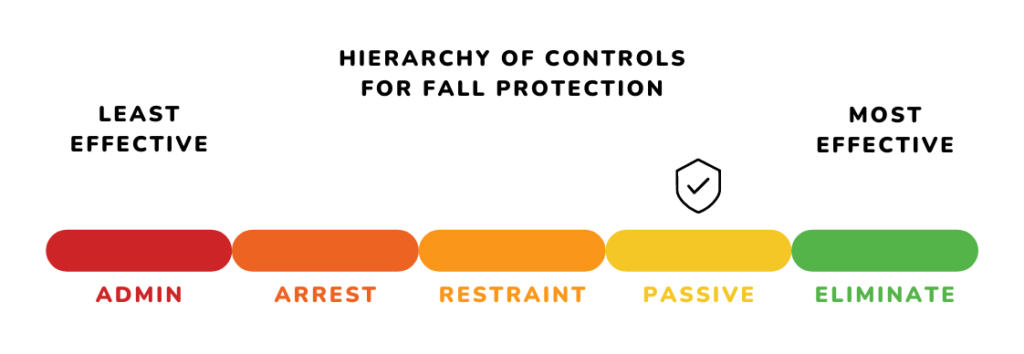

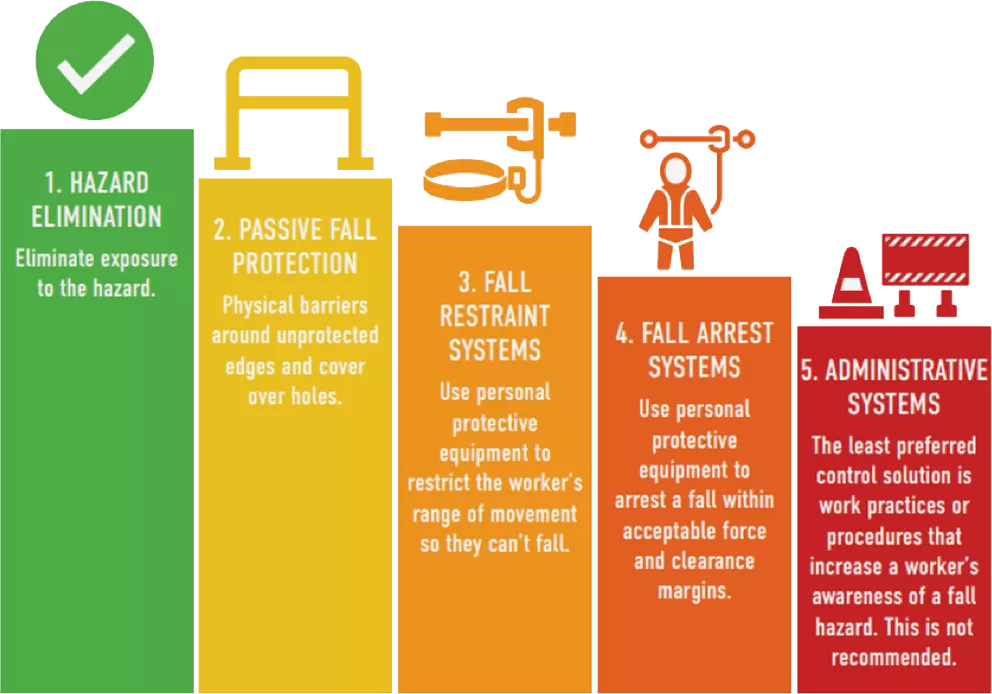

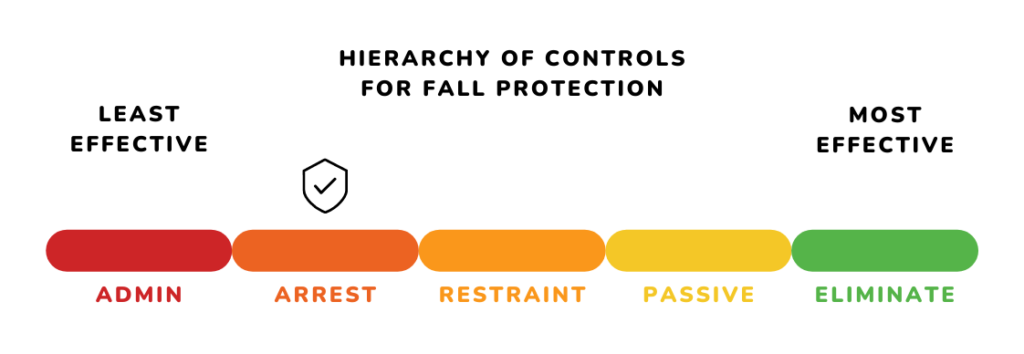

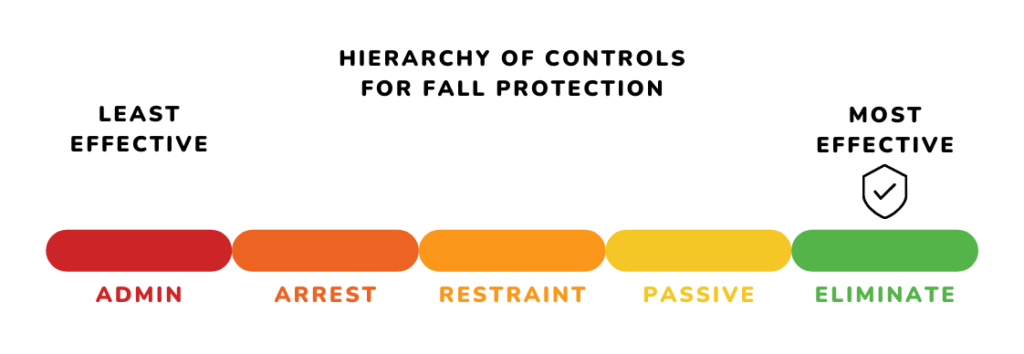

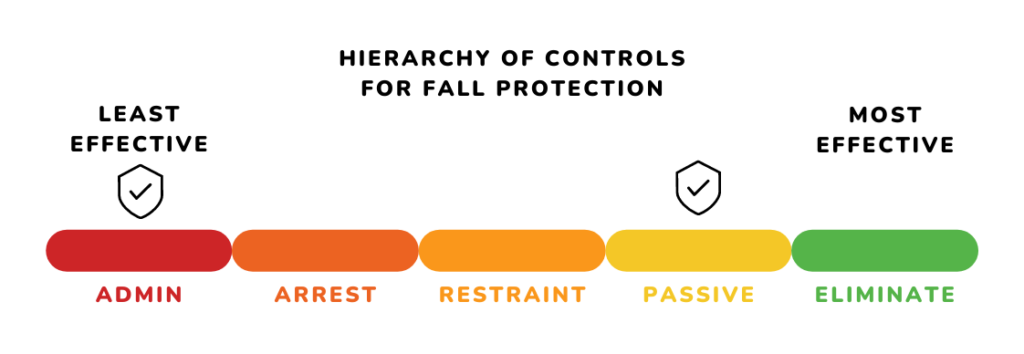

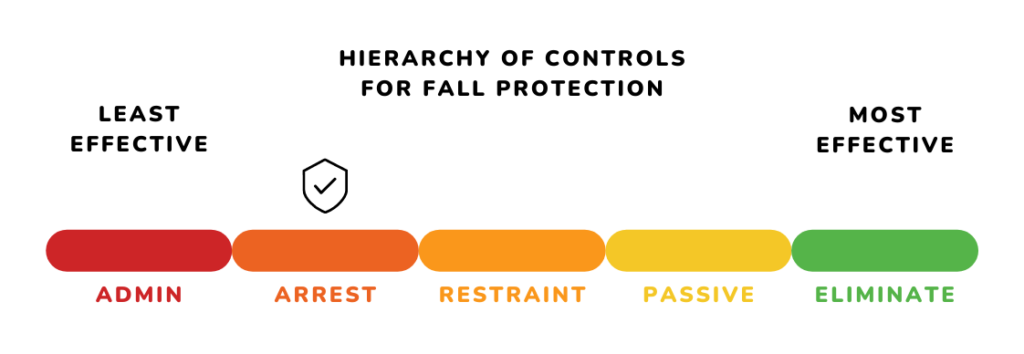

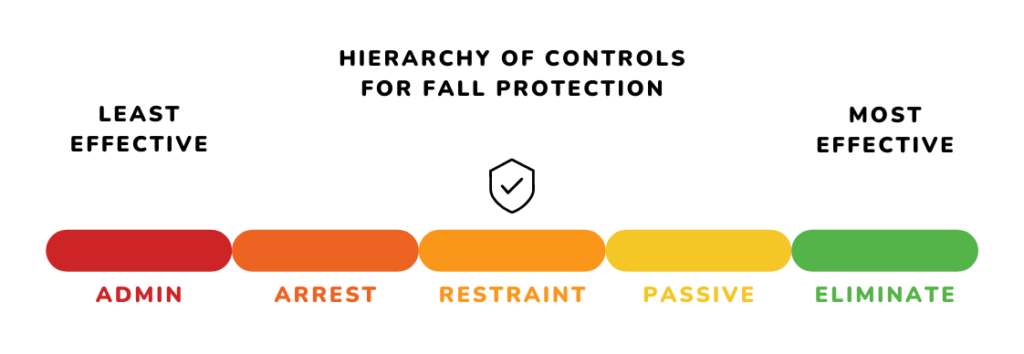

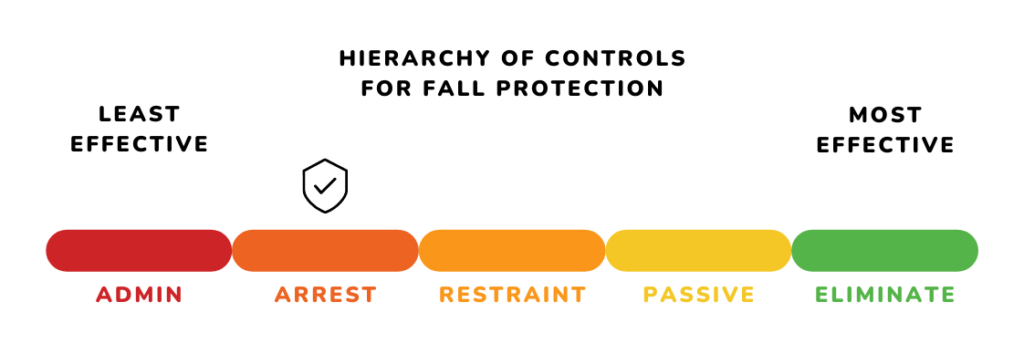

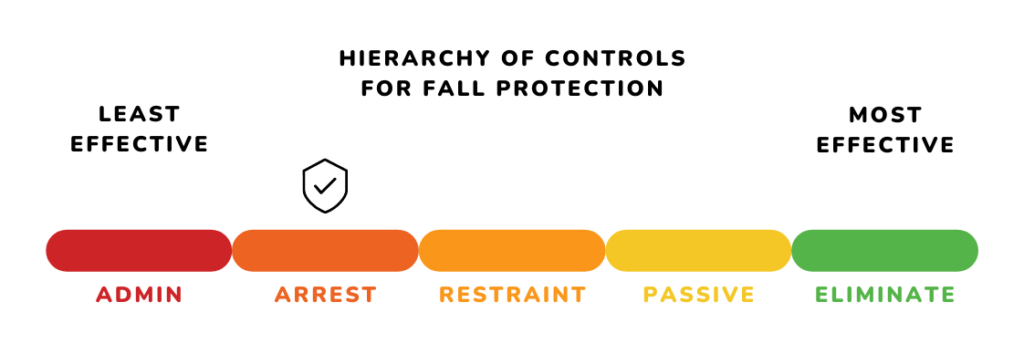

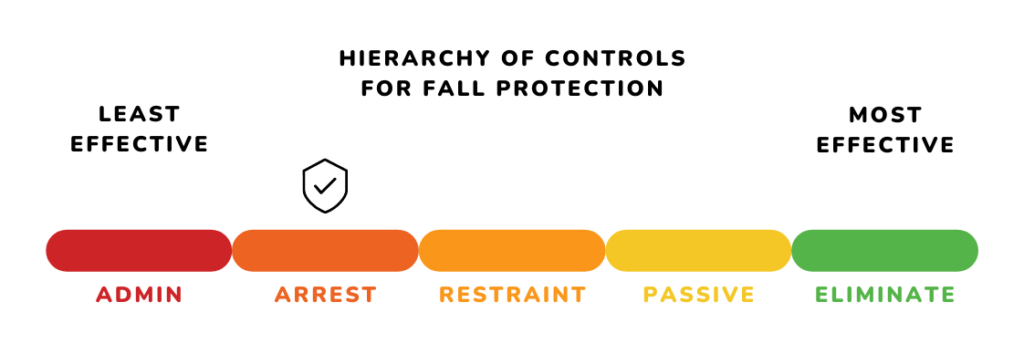

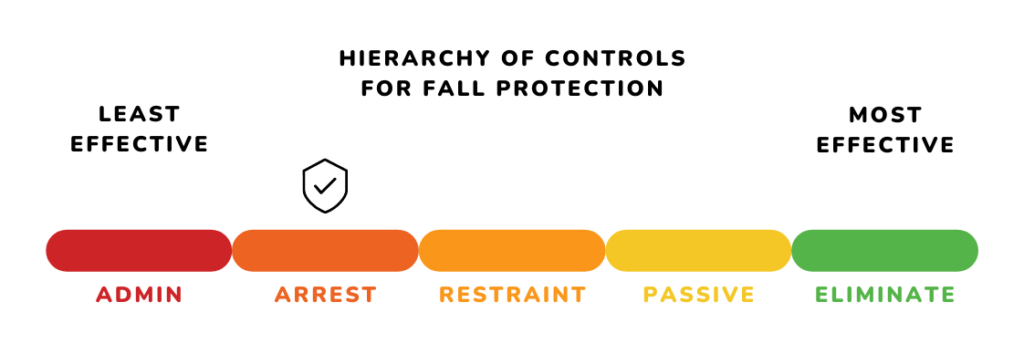

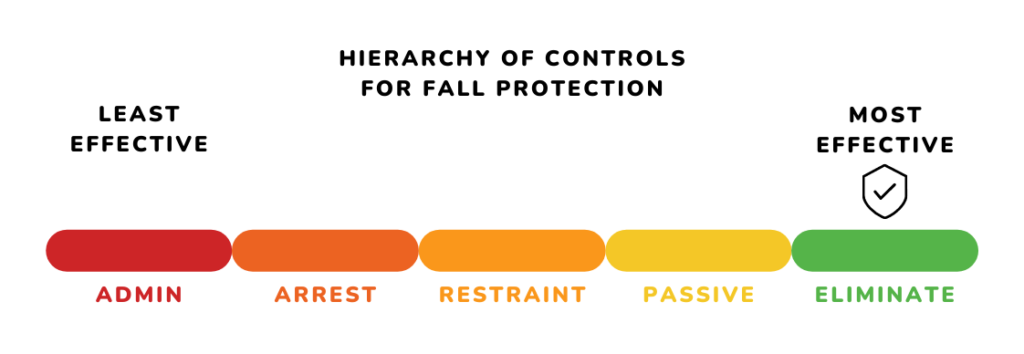

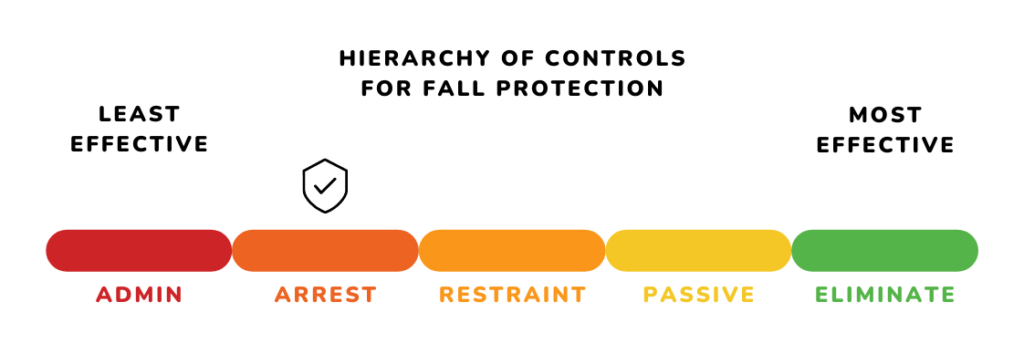

- Types of fall protection systems and how they fit into OSHA’s hierarchy of controls

- The many options and varieties of fall protection solutions on the market today

- Fall protection services that compliment these solutions

- Where to buy fall protection solutions and additional considerations when purchasing

fall protection solutions available today, a high level best fit for each solution and additional information to help facilitate your decisions for the best results.

Exploring Fall Protection Systems and Their Alignment with OSHA’s Hierarchy of Controls

passive protection, restraint systems, fall arrest, and admin controls.

Hazard Elimination

The absolute win of any comprehensive safety strategy starts with eliminating hazards. For fall protection, this could involve designing the work process or the site itself in such a way that working at heights isn’t necessary. This proactive approach effectively removes the risk at its source and sets the tone for an inherently safer work environment. Although this is not feasible in many scenarios, it is OSHA’s favorite and most effective fall protection strategy.

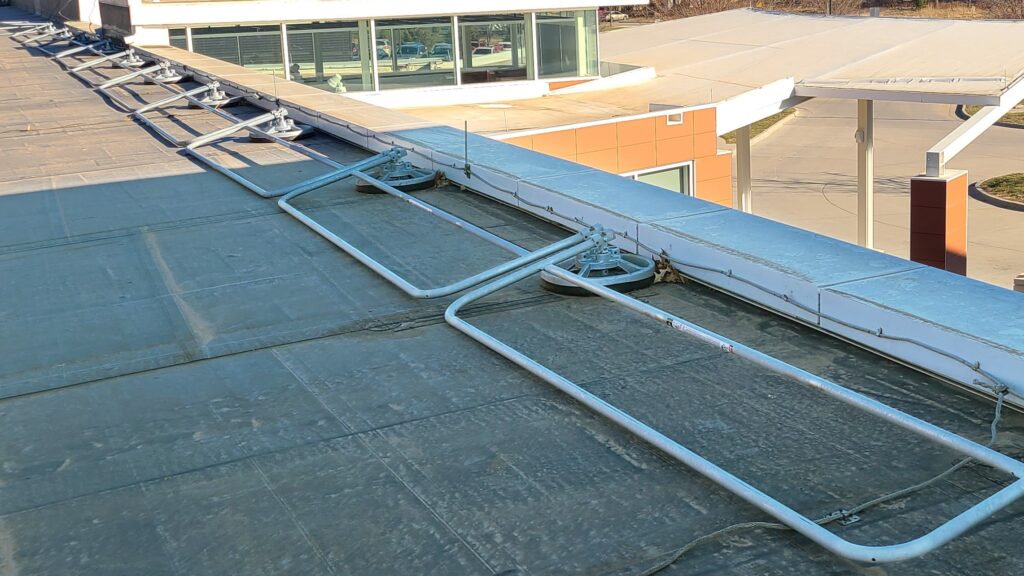

Passive Fall Protection

guardrails, parapet walls, covers, etc. These measures form a physical barrier between your team members and the fall hazard, providing a layer of protection that doesn’t depend on individual actions, making it a robust and reliable line of defense. When hazard elimination is not feasible, this is the next best option.

Restraint Systems

One step further, we enter the realm of fall restraint systems. This active measure involves equipment such as body belts or harnesses tethered to an anchor that prevents your co-workers from reaching the fall hazard. While it requires training and proper usage for your team, this solution works well in situations or at sites where barriers or guardrails cannot be used. This is the midpoint in OSHA’s hierarchy of controls for fall protection.

Fall Arrest Systems

For times when more effective controls are not feasible, fall arrest systems serve as one of the last resorts to save lives. These systems aren’t about preventing the fall, but rather about managing them effectively to minimize injury to your workers. Comprised of components like full-body harnesses, energy-absorbing lanyards, and self-retracting lifelines, these systems work in concert to arrest a fall mid-descent, thereby turning a potentially dangerous fall into a controlled descent and safe stop for recovery.

Administrative Controls

At the tail end of OSHA’s hierarchy, we have administrative controls. This control involves changes in work procedures, like safety training, scheduling work to minimize exposure to fall hazards, and installing warning systems. While these measures don’t directly remove the hazard or limit a fall, they reduce the probability of falls by influencing worker behavior and promoting a safety-conscious work environment. Administrative controls are at the bottom of the hierarchy for a reason and should only be used when all other options have been exhausted as they are the least effective fall protection strategy.

>

Unpacking the Wide Range of Fall Protection Solutions in Today’s Market

Below we’ll provide a high level overview of over two dozen fall protection solutions including where they fall in the hierarchy of controls, pros, cons, and brief description.

Mobile Safety Railing

Provides a portable and adjustable barrier against fall hazards.

Modular Crossover Stairs

Used to provide safe access over obstructions like pipes or conveyor belts.

Rooftop Hatch Guards

Installed around rooftop hatches to prevent workers from falling through open hatches.

Self-Closing Gates

Gates that automatically close after use, ensuring a continuous barrier is maintained.

Anchor Points

Provides secure attachment for personal fall arrest systems.

Placement and installation need to be precise and load-rated.

Used for attaching lifelines, lanyards or deceleration devices, ensuring a secure point of attachment. Anchor points should have a strength capable of supporting 5,000 lbs per worker attached or be designed and installed as part of a complete personal fall arrest system which maintains a safety factor of at least two.

Architectural Safety Railing

Designed to integrate seamlessly with a building’s design, providing a balance of aesthetics and safety.

Cal-OSHA 3209 Safety Railing

Specifically designed to meet the specifications outlined in Cal-OSHA regulation 3209 for preventing falls, which often exceed federal OSHA standards.

Cantilever Dock Gates

These gates are designed to provide full coverage, from the deck to overhead, ensuring comprehensive fall protection at the loading dock.

Drones

Reduces and/or eliminates exposure to fall hazards.

Requires trained personnel to operate along with FAA rules & regulations and setback distances to airports for use.

Drones can be used to access hard-to-reach areas, reducing the need for workers to be exposed to fall hazards for routine inspections, surveys, infrared imaging, etc.

Enduraline Mobile Warning Line

Mobile system for creating a visual barrier to keep workers away from fall hazards. Permanent warning line systems are best used in conjunction with guard rail systems. They are also used to strengthen and reinforce administrative control policies.

Enduraline Warning Line For Metal Decks

Provides enhanced grip and stability on metal surfaces.

Limited to use on metal decks.

Similar to the mobile version, but designed specifically for metal deck surfaces. Permanent warning line systems are best used in conjunction with guard rail systems. They are also used to strengthen and reinforce administrative control policies.

Fall Protection Carts

Provides a versatile solution for varying work conditions.

Only works well on wide open roofs. When activated during a fall, many models make a penetration into your roof requiring repairs and waterproofing.

Mobile anchorage systems that can provide fall protection in various locations.

Floor Mount Safety Railing

Installed directly onto the floor of a work area to provide a barrier against fall hazards.

Fold Down Safety Railing

Provides passive fall protection around perimeters but can be folded down when not in use.

Horizontal Lifelines (HLLs)

Can provide protection for multiple workers simultaneously.

Lines can get tangled. Requires precise calculation and installation to ensure safety.

Systems that allow workers to move horizontally while remaining tied off to a secure line.

Ladder Guards

Top of ladders safety system for controlled access and transition onto flat roofs.

Mezzanine Safety Gates

Protects workers from falls on mezzanine edges while loading and unloading goods.

Metal Deck Safety Railing

Designed to provide roof fall protection on metal deck surfaces usually via standing seam clamps.

Wall/Pit Safety Railing

Typically installed around the perimeters of pits, walls or floor openings to prevent falls. These railings provide a physical barrier to protect workers from fall hazards.

Parapet Wall Safety Railing

Installed on low height parapet walls to provide a protective barrier against falls.

Personnel Fall Safety Netting

Provides an additional layer of protection when used in conjunction with other fall protection systems.

Can be difficult to install in some situations.

Installed under high work areas to catch falling workers and reduce fall distances.

Rigid Rail Systems

Allows for smoother horizontal movement and can reduce fall distances.

Requires professional installation and regular inspections.

Allows workers to move vertically and horizontally while tied off, offering fall protection and easier rescue capabilities.

Self-Retracting Lifelines (SRLs)

Reduce fall distances and resulting forces exerted on a worker during a fall which reduces injury severity.

Can be costly and require regular inspection and maintenance.

Connects the user’s fall protection harness to an anchor point, locking instantly in the event of a fall to minimize fall distance.

Skylight Guards

Installed around skylights and sometimes overhead to prevent workers from falling through the skylight.

Skylight Screens

Screens installed over skylights to prevent falls through often brittle or fragile skylight material.

Tethering Fall Protection for Tools

Prevents dropped tools, increasing safety and productivity.

Requires workers to adjust to the tethering system and may interfere with work.

While our primary focus is preventing people from falling, preventing tools from falling is a close second as they can be fatal projectiles to workers below.

Telescopic Tools

Allows for work from a safe distance or height, reducing worker fatigue and increasing efficiency.

Not suitable for all types of work. Tasks such as window washing, solar panel cleaning, lighting replacement, inspection feasible with lighter tools.

These tools extend the reach of workers, allowing them to perform tasks at height from a safe, grounded location, thus eliminating most/all fall hazards.

Vertical Lifelines

Provide secure protection for workers needing to ascend or descend vertically. Very helpful in tower maintenance.

Can limit the worker’s horizontal movement and requires careful setup and training to ensure safety.

Utilized when workers need to ascend or descend vertically, these systems provide a secure line that workers can tie off to, ensuring safety while moving vertically.

>

Fall Protection Services that Compliment Safety Solutions

Next, we’ll be discussing a few fall protection services to consider from the solutions above: hazard assessment, where we identify potential risks; engineering/modeling, involving the creation of effective safety designs; and installation, where we apply these designs to enhance your safety setup.

Hazard Assessments

hazard assessments in line with OSHA guidelines. This service is pivotal in identifying fall hazards, elements in the worksite that could cause a fall. Additionally, we develop fall control strategies, deploying safety equipment and training to mitigate the risk of falls. Our hazard assessment process entails a thorough identification of risks, using pre-existing data, conducting on-site inspections, investigating past incidents, and anticipating hazards in unusual circumstances. Once identified, we prioritize and execute corrective actions to mitigate these hazards.

Engineering & Modeling

Our engineering and modeling services are executed by highly skilled engineers, backed by industry-leading software like SolidWorks, to create safety designs tailored to your site’s unique needs. The engineering process involves meticulously modeling potential fall hazards and developing effective countermeasures. Leveraging advanced 3D design capabilities, we create precise, realistic models of your worksite to ensure our safety solutions seamlessly integrate with your existing infrastructure.

Installation

installations. Their safety training, expertise, and familiarity with various projects ensure competent handling, regardless of size or location. We stay transparent by providing full documentation of the process, allowing clients to feel secure, knowing their installations are managed by insured and responsible professionals.

>

Key Considerations When Selecting a Fall Protection Solutions Provider

Compliance Standards: Ensure that the products meet or exceed all relevant regulatory safety standards like OSHA, ANSI, and any industry-specific requirements. This is non-negotiable, especially for larger companies with high visibility.

Scalability of Solutions: Consider if the supplier can handle the scale of your operations, from single-site installations to nationwide, multi-location projects.

Customization: Does the manufacturer provide custom solutions? Many companies have unique needs that off-the-shelf products might not address.

Expert Consultation & Support: The supplier needs to be a partner who provides expert consultation on the best safety solutions for your company’s unique needs.

Training Programs: The manufacturer should offer comprehensive training programs on the proper usage and maintenance of the safety equipment, suitable for the size and needs of your staff..

Reliability and Durability of Products: High-quality, durable equipment is crucial to protect your workforce and reduce the risk of work stoppages due to equipment failure.

Established Track Record: The provider should have a solid reputation for serving small to large-scale operations. Consider their history with Fortune 500 companies.

Product Innovation: Look for suppliers that lead in technological advancements and innovation, offering the latest in fall protection solutions.

Insurance and Liability Coverage: Ensure that the supplier carries adequate insurance, particularly liability coverage in case of equipment malfunction or safety issues.

Post-Purchase Support and Services: A top-tier manufacturer will offer excellent after-sales service, including regular maintenance, inspections, and quick response for any emergencies or issues.

>

>

Fall Protection Equipment & Solutions Wrap Up

Choosing the right fall protection solutions is vital for worker safety. Take into account OSHA’s hierarchy of controls, the various fall protection systems, and additional services like hazard assessments, modeling, and installation in your vetting process. Look for a manufacturer that meets compliance standards, can scale, offers customization and has a record of product reliability. Insurance coverage and post-purchase support are also very important.

Informed decisions lead to safer workplaces and a workforce that can confidently return home safe each night.

please reach out to our fall protection experts, we’d be happy to help.

Thank you for reading and stay safe!