Who is responsible for conducting a hazard assessment: Fall Protection Edition

Hazard Assessment Responsibility?

The short answer – Under OSHA guidelines, employers are responsible for conducting fall hazard assessments to identify and assess the potential risks in their workplace. We’ll get into more detail below around this topic including key terms and definitions, the fall hazard assessment process and job responsibility and common tasks.

Key Terms & Definitions

Fall Hazard

A fall hazard is anything at your worksite that could cause you to lose your balance or lose bodily support and result in a fall. Any walking or working surface can be a potential fall hazard. Any time you are working at a height of four feet or more, you are at risk. OSHA generally requires that fall protection be provided at four feet in general industry, five feet in maritime and six feet in construction. However, regardless of the fall distance, fall protection must be provided when working over dangerous equipment and machinery.

Fall Risk

In the construction industry, a fall risk is an individual who works at height and may be exposed to falls from elevation that can result in serious injury or death. Common factors that influence and increase fall risks for workers include: age, muscle strength and conditioning, balance and coordination, vision issues and impairment, medication and/or substance use, worker fatigue and extreme hot/cold temperatures.

Fall Control

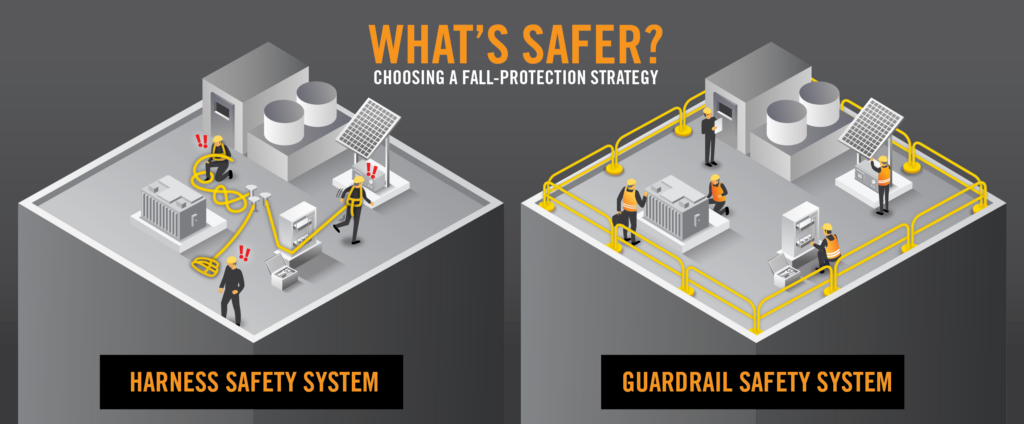

Fall control is a system of measures used to reduce the risk of falls from height. These systems often include guardrails, safety harnesses, and other types of safety equipment that are designed to prevent workers from falling off elevated work surfaces or from high places such as scaffolding or ladders. Fall control also includes practices like proper worker training, regular maintenance of safety equipment, and safe work procedures for working at height.

Fall Hazard Assessment Process

Establishing a comprehensive understanding of the fall hazards present in the workplace through the diligent gathering of pre-existing data

How To & Helpful Tips

- Interview your various teams and ask them for feedback. Where have they felt unsafe or uncomfortable? Where is a work area that would cause them concern with a new hire?

- Look at existing fall protection equipment and guarding that is in place. Is it in good working condition? When was it last replaced?

- Review roofing inspection and any associated insurance reports

- Review previous workers’ comp reports involving ladders, falls, scaffolding, etc.

- What do the existing safety programs look like for work from heights, lockout/tagout, confined spaces and PPE

- Look outside of your workplace and gather insight from other safety professionals

- Consider joining safety organizations like Institution of Occupational Safety and Health (IOSH), National Safety Council (NSC) or American Society of Safety Professionals (ASSP) for additional help and resources

Conduct an on-site inspection for potential fall hazards in the work environment

How To & Helpful Tips

- Schedule and conduct inspections at an appropriate cadence that matches the potential fall hazard

- During the inspection photo and document fall hazards. This information can then be stored in your Environmental Health and Safety (EHS) software and also used for future safety training

- When inspecting your facility for fall hazards, put yourself in the boots of an everyday employee, construction worker and maintenance person. Their overlap will probably be easier to identify, but look for those unique hazards that others may miss

- Cross train your team in fall hazard inspection to increase awareness and overall team safety

Conduct investigations for fall incidents at your workplace

How To & Helpful Tips

- Have a plan in place for who is responsible for conducting the investigation internally and who will be the point(s) of contact for the hospital, OSHA, and additional parties

- For Injuries and near miss incidents, safety professionals should be familiar with OSHA’s Form 301 – Injury and Illness Incident Report

- Important details include but are not limited to:

- If treatment was given away from the worksite, where was it given?

- Was the employee treated in an emergency room?

- Was the employee hospitalized overnight as an in-patient?

- Date of Injury or Illness?

- Time Employee began work?

- Time of Event?

- What was the employee doing just before the incident occurred?

- What Happened? Tell us how the injury occurred

- What was the injury or illness?

- What object or substance directly harmed the employee?

- If the employee died, when did death occur?

- Date of death?

- Note that OSHA must be notified within 8 hours of work-related fatality and within 24 hours for an amputation, loss of an eye or hospitalization.

- Use the 5 W + H questions: what, where, when, who, why, and how to find the root cause(s) of the incident and ways to prevent it in the future.

Identify hazards that may arise during unexpected emergencies and/or during unusual circumstances or events

How To & Helpful Tips

- Daily, weekly and monthly activities have built in routines. What activities are completed at your facility on a quarterly or annual basis that may have unidentified embedded hazards?

- What safety procedures are in place for crane lifts onto roofs?

- What safety protocols do you have in place to prevent a worker from being locked out on a roof?

- What is your policy around adverse weather (rain, snow, lighting, heat, cold) and roof work?

- If a worker experiences an illness on your roof like heat stroke or if they fall from one roof level to another what safety plans and training do you have in place to rescue them?

- If a worker that is tied off does fall from heights, what is your process for finding and rescuing them?

Evaluate hazards and prioritize corrective actions

How To & Helpful Tips

- What are the potential fall hazards?

- Unprotected rooftop skylight by roof hatch where workers enter/exit

- Rooftop ladder with no self closing gate or cage

- Open hatch on roof

- Stairway without railing

- Multi-level flat roofs

- Rooftop ladder going between two levels (24 feet) used by 6-8 staff every few weeks for rooftop scientific observation and measurement. If a member of staff fell the most likely incident would be death so these fall hazards would be highly prioritized ideally with a caged ladder, self closing gate at the top of the ladder and safe transition from ladder to scientific instrumentation.

- Rooftop safety rail, visual warning lines and a rooftop hatch guard with self closing gate.

- Rooftop corner rail that accommodates a parapet wall.

- While installing equipment on a roof a team of four subcontractors needs to traverse a multi-level commercial flat roof via roof hatch to complete their installation. If a worker fell from one roof level to another, from the roof to the ground, or through the open roof hatch into the mechanical room the most likely incident would be death. These fall hazards would be highly prioritized ideally with rooftop safety rail, visual warning lines and a rooftop hatch guard with self closing gate.

- What are the potential fall hazards?

- Unprotected rooftop skylight by roof hatch where workers enter/exit

- Rooftop ladder with no self closing gate or cage

- Open hatch on roof

- Stairway without railing

- Multi-level flat roofs

- Rooftop edge crane loading area

- How often are workers exposed to the fall hazard?

- Hourly, daily, weekly, monthly, quarterly, annually

- How many workers are exposed to the fall hazard?

- What potential incident(s) would result from exposure to the fall hazard?

- Minor injury, major injury, paralysis, death

- Prioritize fall hazards and put the proper controls in place to reduce or if possible eliminate risk