Toe Board Safety: Proper Use, Applications and Tips

Background & Use of Toe Boards

When working from heights, commonly in the roofing and/or construction industry, there is a constant need to safely and efficiently perform site work. Part of that process includes using a variety of systems and protocols to mitigate unsafe work environments. Toe boards (also called toe kicks) are a part of that system that we will be further focusing on in this article.

What is a Toe-board?

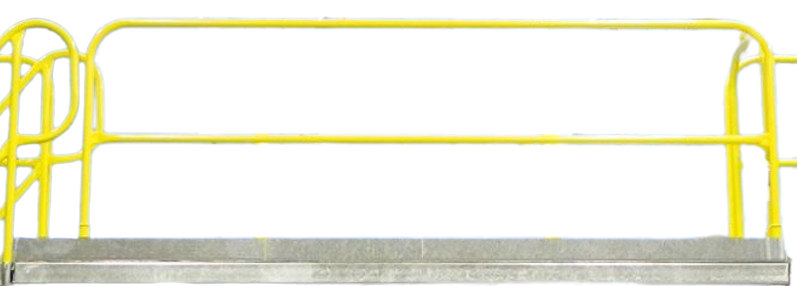

A toeboard is a physical barrier that runs along a fall edge that prevents people and objects from falling to a lower surface. Traditionally, toe boards are made of wood (most commonly Douglas Fir) 2’x4’s that match the length of the guardrails they are associated with. While wooden toe boards are still used in some applications, many toeboards are made of metal for increased strength and longevity.

Toeboards and Fall Prevention: Workers and Equipment

For people, toe boards are often an essential safety device for anyone working on flat and low slope roofs. They provide a barrier between the worker and the fall edge of the roof, helping to prevent them from slipping or sliding off. Toe boards should always be used when working near a roof’s edge (unless there is a parapet wall) because they can help prevent slips and falls that could lead to serious injury or death. Additionally, toe boards can be used with guard rails to block off hazardous areas on a roof, such as skylights or large holes.

Common Items that Fall from Heights

- Building Materials

- Construction Debris

- Power Tools

- Wrenches

- Chisels

- Circular Saws

- Hammers

- Crowbar

- Disc Sanders

- Ladders

- Nail Gun

- Pliers

- Level

Equipment and tools are also essential components on construction projects. While they are not the primary focus for fall protection, they can present a significant safety hazard if not managed properly. According to the Bureau of Labor Statistics, every day in the US, there are more than 115 OSHA recordable events related to “struck by falling object” incidents.

On average, there are 42,000+ “struck by falling object” OSHA recordable events in the US annually.

Common Areas & Applications for Toe Kick Boards

- Rooftops & Roof Edges

- Scaffolding

- Elevated Work Platforms

- Catwalks

- Low Slope Roofs

- Mezzanines

- Machine Platforms

- Crossover Ladders & Stairs

Tips to Use in Conjunction with Toe Boards

- Having onsite tool storage areas allows workers to easily locate and store tools when they are not in use. This reduces the amount of tools that need to be taken out into the field, reducing potential drop hazards while also improving job efficiency. Additionally, consider utilizing tool tethers so that if a tool is dropped, it can be safely secured before it hits someone.

- It is important to not underestimate wind strength on rooftop construction projects. If you’re building something at a high elevation, expect to deal with more intense winds than if you were building at a lower altitude. Fastening down items like plywood that lack ballast is especially important in these situations as they are prone to being blown away, hitting people & property and causing damage.

- When assessing potential drop zones, consider the direct drop of tools along with the ricochet effect. Dropped tools can cause serious injury or death if they strike workers below. Ricocheting tools may reach unexpected areas below and increase the probability of harm to those in the vicinity. To prevent these hazardous scenarios, it is important to examine the area for potential objects that can be struck and cause ricochet. Furthermore, any tool drops should have buffers in place to ensure that no one standing below will be injured in the event of a drop.

Toe Boards & OSHA Standards

This section would detail the relevant OSHA standards and how they apply to toe boards, ensuring compliance and safety in the workplace.

Thank you for reading and stay safe!