Roof Safety Equipment: What You Need to Know to Keep Your Workers Safe

“Your employees’ safety and health are the keys to the success of your business” – H. W. Heinrich.

As an employer, keeping your workers safe should always be a top priority. Their safety becomes even more important when they are working from height. There are a lot of potential hazards when working on a roof. This is why it’s imperative to have the right safety equipment in place to prevent injuries or worse, fatalities. In this article, we’ll go over some of the most essential roof safety equipment. Plus, we will cover topics you need to know to keep your workers safe when working from height.

Safety Background

After the Occupational Safety and Health Act was passed back in 1970, Congress established the Occupational Safety and Health Administration (OSHA). This regulatory agency provides robust federal standards aimed at making workplaces safe and healthy for employees. The primary focus of the organization is to promote safety in the workplace. They accomplish this by crafting and implementing regulations designed to protect workers from hazards. Other areas of focus include training staff on proper processes, encouraging actions that prevent workplace-related injuries, and monitoring adherence with established protocols. Additionally, OSHA provides resources like education and outreach/training materials. They encourage employers to establish safety programs as well as other activities that help improve working conditions throughout the US.

Specifically, OSHA has established detailed regulations that focus on the following areas related to roof safety:

- Fall Protection: OSHA requires employers to provide fall protection for employees who are working on roofs that are 4 feet or more above lower levels. In general, fall protection systems can include guardrails, safety nets, personal fall arrest systems and more.

- Hazard Communication: OSHA requires employers to train their workers on the hazards of working on roofs. This includes potential hazards related to roof access, roof materials, and roof equipment.

- Personal Protective Equipment (PPE): OSHA requires employers to provide and verify the use of appropriate PPE. Hard hats, safety glasses, and non-slip footwear are some examples.

- Ladder Safety: OSHA requires employers to certify that ladders used for roof access are in good condition, properly secured, and the right size for the job.

- Heat Illness Prevention: OSHA has also established guidelines for preventing heat illness in workers who are working on roofs in hot weather.

Overall, OSHA’s regulations help to ensure that roof workers are protected from falls, hazards, and other safety risks. Employers who do not comply with OSHA’s regulations may face penalties and fines. You can learn more about OSHA inspections by reading this blog.

What Should Be Included When Thinking About Roof Safety Systems?

Rooftop safety equipment is essential for workers who need to perform regular maintenance or construction work on rooftops. This equipment helps to prevent falls, which can be deadly. The type of safety equipment needed will depend on the type of work being done and the height of the building. Some examples of roof fall protection equipment that should be included for workers are:

Personal Protective Equipment

PPE is crucial in preventing injuries on the rooftop. Workers should wear non-slip shoes, hard hats, and high-visibility clothing to ensure they are visible to others. Gloves and eye protection are also very important to protect against various hazards.

Fall Protection Systems

Fall protection systems include guardrails, safety nets, and personal fall arrest systems. These measures are essential for preventing workers from falling and sustaining injuries.

Warning Lines

Warning lines are used along with guardrail systems to provide additional visual cues to prevent workers from approaching edge areas that pose fall risks.

Access Equipment

Proper access equipment, such as ladders and scaffolds, must be used for safely reaching the rooftop. This equipment must be regularly inspected and maintained to ensure it is safe to use.

Weather Protection

Workers on rooftops should also have protection from the weather. This may include shade structures, umbrellas, or shelter from rain or snow. OSHA recommends that work should stop and seek shelter when they hear thunder. Remember, lightning can strike even if it is not raining. Work can be resumed 30 minutes after the last observed lightning or thunder.

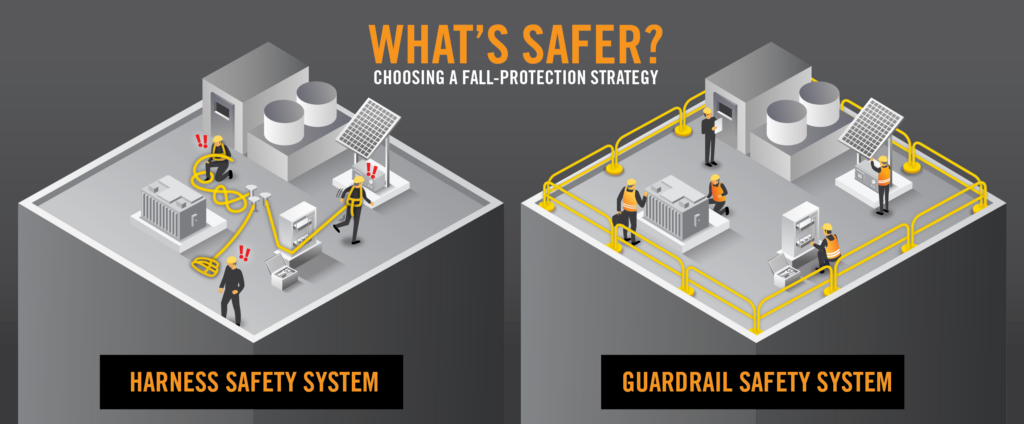

What is the Difference Between an Active & Passive Fall Protection System?

Passive and active fall protection are the two main systems when it comes to preventing workers falling from height. Active fall protection relies on the workers to actively engage with the system. This includes using harnesses, lanyards, and anchors to secure themselves while working at height. This type of system requires ongoing training to ensure employees use the equipment correctly and regularly inspect and maintain it. Passive fall protection, on the other hand, consists of physical barriers and structures that are put in place to prevent falls. Examples of passive fall protection include guardrails, hatchguards, skylight guards, and self-closing gates and covers for holes in the ground. This type of protection does not require worker participation and is always present and ready to prevent falls. Passive fall protection is generally considered to be the superior option due to its inherent reliability and ease of use. It does not require workers to remember to engage with the system, reducing the risk of human error. Passive protection can also be more cost-effective and have a longer lifespan than active protection systems. In fact, OSHA recommends the use of passive fall protection wherever possible. OSHA prefers passive protection because it eliminates the potential for worker error and is generally more reliable. Please contact the safety experts to discuss which system will work best for your company.

Your Roof Safety Equipment Has Been Installed, Now What?

It’s not enough to install the proper fall protection equipment for your employees and call it a day. It is imperative for employers to stay up to date on the latest roof safety regulations, to make certain that their workplace is in compliance in order to keep their workers safe on the job. Here are a few steps employers can take to stay on top of roof safety regulations:

- Stay informed: Employers need to stay informed about current and or upcoming roof safety regulations, as well as any changes/updates to existing ones. This can be done by routinely checking government websites, attending training sessions and subscribing to newsletters or other sources of information.

- Conduct regular assessments: Employers should perform thorough assessments of the workplace to review existing and identify any new potential fall hazards. Specifically, this can include inspecting the roof itself, as well as any equipment or materials that workers use while on the job.

- Provide training: Training on the latest roof safety regulations and best practices needs to be provided by employers regularly. This can include training or a refresher on how to properly use PPE, how to recognize and avoid hazards and what to do in the event of an emergency.

- Implement safety protocols: Employers should administer safety protocols to establish that their workplace is in compliance with OSHA’s roof safety regulations. This can include protocols for inspecting and maintaining equipment, protocols for responding to emergencies, and protocols for reporting and investigating accidents or incidents.

Conclusion

It is imperative for employers to provide their employees with the proper and necessary roof safety equipment to protect those who work at heights. Thankfully OSHA’s established and detailed regulations make it simple for employers to follow. Afterall, a great employer will do everything they can to protect their valuable employees. So whether you install guardrail systems or opt for a fall arrest system, choosing safety for your workers is always the right answer.

Thank you for reading and stay safe!